visibility measurement for ADAS and autonomous véhicle

NEXYAD launched the new release V2.0 of their visibility measurement module VisiNex Onboard :

To read more : http://nexyad.net/Automotive-Transportation/?page_id=438

NEXYAD launched the new release V2.0 of their visibility measurement module VisiNex Onboard :

To read more : http://nexyad.net/Automotive-Transportation/?page_id=438

(version française ICI)

Visibility measurement can be accomplished in several ways:

- Very basic methods measure the attenuation of a light beam as a function of distance, in transmission ( through the mist , for example) or in reflection ( to test the effectiveness of the markings on the roads to improve visibility) .

- Heuristic approaches that measure the contrast of images and calibrate heuristically in terms of visibility

But there is a much more rigorous approach (both general about the possible causes of reduced visibility , and totally correlated to human perception ) : the Johnson criteria .

The approach is to compare the available contrast on each angular frequency , with the contrast that is necessary for human perception to detect, recognize and identify objects .

It is therefore a human factor driven approach , and not an approach of physicist working on the transmission of a light signal.

This approach is implemented in a commercial tool ( VisiNex ) developed by the French company NEXYAD .

It is therefore possible to make accurate measurements , repeatable and 100% correlated with human perception :

- in Laboratory : with VisiNex tool

- In the real world with an embedded version of VisiNex : Onboard VisiNex

For more information : http://www.nexyad.com and click activities NEXYAD Testing and NEXYAD Automotive & Transportation

(en Français cliquez ICI)

Measurement of visibility is an issue that has preoccupied first the military applications : depending on weather conditions, how far watcher can see a potential threat ?

Military vocabulary defines 3 functions:

- Detection: I see a point in the sky

- Recognition: it is a helicopter

- Identification: it is such helicopter model

This work has been carried out since the 60s, by the U.S. Department Of Defense (in particular), and the major developed models (of human vision) are based on a frequency approach (angular frequency): the eye and the human brain need the scene to respect a compromise between three characteristics, in order to distinguish shapes, :

- contrast

- Accuracy and number of gray levels (for a digital image, it depends on the number of bits)

- Size of objects

So we can clearly see:

- Stars in a night sky: the number of gray levels is low, the object size is small, the contrast is strong.

- Gray clouds in a gray sky: the number of gray levels is high, the size of objects is large (and there is no high spatial frequencies), the contrast is low.

Partial published mathematics models must be coupled to build a predictive system of visual performance of a watchman:

- contrast sensitivity of the eye in function of angular frequency

- Sensitivity of the eye to the ambient luminance

- Sensitivity of the eye to color

- Daytime vision and night vision

- ...

On these models, the so-called Johnson criteria give how far we need to come closer, when we detected a shape, to recognize and to identify it. These criteria are compatible with the pre-mentioned mathematical models because they are expressed in "cycle per degree", that is to say 'angular frequency'.

The company NEXYAD has developed an industrial tool for measuring visibility. This tool comes in two forms:

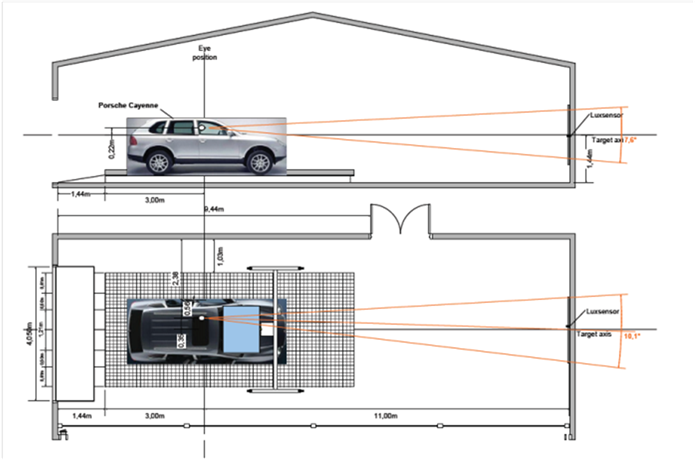

- A laboratory tool (or plant): it is a tool for measuring the visibility implementing structured patterns and lighting skills: VisiNex

(http://www.visinex.net/)

- A tool for open world (road environment, airports, ports, etc.) visibility estimation : it is a sensor visibility:

Onboard VisiNex

These tools use both a standard camera, they are used by many manufacturers, and have been tested in numerous industrial and real world applications. They are proven, Their distinctive feature is that they do not give the same detection distance depending on the size of the objects to be detected (truck, light vehicle, bicycle, pedestrian, pavement on the road ...).

Moreover, these tools provide the ability to identify the type of disturbance that lowers visibility (fog, rain, shadows, ...).

For more information:

VisiNex: http://nexyad.net/Automotive-Transportation/?page_id=159

VisiNex Onboard (measurement of visibility in front of a car): http://nexyad.net/Automotive-Transportation/?page_id=74

NEXYAD: http://www.nexyad.com

(version Française ICI)

Measuring the road scenes visibility is a topic studied since the 60s and several approaches have been developed. Most measurements using a laser and a receiver, measure the attenuation of the light power transmission to study the influence of atmospheric disturbance , or of the light power reflection to study the power of raising the visibility of road markings .

This measure is easy to implement on a roadside , but it has some major drawbacks:

- It is assumed that the atmospheric disturbance of visibility is isotropic (which is not necessarily the case )

- It depends on the distance between the transmitter and the receiver ( it then requires a model of the atmospheric disturbance to deduce the attenuation on a few hundred meters - generally because the measurement is made over a short distance ) ... and if the disturbance of visibility is localized (like a fog ), it is not certain that the sensors are present precisely at the location of the disturbance ... or you should deploy sensors throughout the infrastructure.

- It does not look the markings under the same angle as the driver

- It ignores the characteristics of human vision that does not need the same image quality for " good view " , depending on the size of the objects that compose the scene, according to the ambient brightness, etc.

- It is not take int account systems used to restore the visibility while driving ( wipers , lighting, ... ) and the interaction with the road infrastructure.

For all these reasons , it is interesting to have a "true " measurement of visibility, ie a measure that react exactly like the human visual perception system .

The most advanced works in this area come from the military sector where stealth considerations are very important. Early on , the military wanted to have theoretical models for predicting the probability of detecting a stationary soldier or a tank in its wooded surroundings , for example, depending on camouflage used.

The selected models describe the human vision on several fronts:

- Sensitivity of the eye to the wavelength ( color )

- Sensitivity of the eye to the contrast

- Sensitivity of the eye to the object size

- Influence of light level on visual performance

- Etc ...

The company NEXYAD aggregated all of this work and has integrated them into a single tool for measuring visibility : VisiNex .

VisiNex (http://www.visinex.net/) is de facto a standard because it is the only product in the world that provides a visibility measurement system used by several industries -with 100% correlation with human eye :

- Automotive : vehicle has organs to restore visibility ( lighting, wiping the windshieldn washing, demisting , defrosting , ... ) . By measuring changes in visibility during the use of these organs under controlled perturbation (eg a machine calibrated artificial rain as RainNex ) , the effectiveness of these bodies is measured, the level of visibility they can restore and how quickly they restore . VisiNex is used by automotive manufacturers and suppliers .

- Road infrastructure : road infrastructure implement labeling techniques and road lighting to enhance the visibility of the road. It is advantageous to have a visibility measurement to characterize the effectiveness of these techniques, any time and for all levels of wear ... VisiNex is in this context used , among other things, by road markings manufacturing companies.

VisiNex The tool also uses the results of military work called " Johnson's criteria " that predict , for a given level of disturbance (eg rain on the windshield, regularly swept by the wipers ) and at every moment , the driver's ability to detect objects , to recognize , to identify them.

For more information : http://nexyad.net/Automotive-Transportation/?page_id=159

Needs for visibility measurement

The visibility measurement is potentially useful for several kinds of applications :

- Industrial application to test the optimal setting for auto systems to restore visibility :

lighting , windshield wiper washing demisting , defrosting ...

- Industrial application of testing and validation markings intended to enhance the visibility on the roads.

- Application to ADAS ( in-vehicle/onboard systems for driver assistance ) : visibility measurement and control of wipers and other restoration visibility systems

- Measurement of meteorological visibility at airports

principles

Measuring visibility " for humans " requires "knowing" the human vision system in order to have a predictive model of that we can "see" or not . Human vision needs a specific compromise between contrast , the accuracy of the luminance, and size of the objects.

There are many model ( Ngan , etc ...) but it is necessary to modulate them depending on parameters such as ambient light , duration of observation , colors , movements, etc ...

Similarly, these models must be modulated to take into account several ( "standard" vision , myopia corrected , elderly , etc ...) types of observers .

In simplified terms , we may say that the more objects are small (we're talking high angular frequency ) , the more it needs contrast detect them.

On these rather complex models, it is possible to add criteria , such as Johnson's criteria , for example, which are predictive of the ability of a human observer to detect , recognize, and identify an object in a scene.

This type of criteria was used initially by military research teams to test camouflage tanks, among others .

The graph below shows that the more angular frequency is high (little objects : thin lines here ) , and the more it takes contrast to detect. Try counting the bands, just to make sure of this.

One can see this compromise on real images : one can easily detect gray clouds on a gray background , the objects are large , the number of different gray levels is great, the contrast is low. And one can also detect stars in a black sky : objects are small, the number of gray levels is very low ( 2 levels: white and black) , but the contrast is very strong ...

very low contrast (no contour and yet we very high contrast (shapes bounded by an edge)

clearly see the shapes of the clouds). Very poor image grayscale, and high contrast.

rich grayscale.

Industrial Tools and practical achievements of visibility measurement

The company NEXYAD has developed a tool to measure visibility. This tool (VisiNex) is used by the automotive industry to test the effectiveness of organs for restoring visibility lighting, wiping the windshield washing, demisting , defrosting ...

VisiNex is also used by manufacturers of road infrastructure to test the effectiveness of road markings which aims to increase the visibility in all weather conditions .

This tool predicts a detection distance ( or range of vision ) , and incorporates the Johnson's criteria to estimate the distance of recognition ( it is a vehicle , it is a sign ...), and identification ( " reading " mode: this is such a vehicle , the panel says this or that ...).

NEXYAD also developed an embedded module for measuring road visibility , VisiNex Onboard , intended as a fundamental building block in ADAS and future autonomous vehicles . This brick has been developed since 2003 , and is subject to improvement and curing since .

For more information : http://www.nexyad.com/Automotive-Transportation

Introducing VisiNex : http://nexyad.net/Automotive-Transportation/?page_id=159

Contact: sales@nexyad.net

Visibility is one of the key factors of road safety. If the driver can not see anything , or is unclear , the probability of accidents is hight.

It would be important then to measure visibility onboard ... This is currently done in a very indirect way : rain sensors , for example, detect the presence of rain on the windshield, and rain is a problem because it lowers visibility ( the wipers are made to restore it ).

However, it is possible to measure visibility from a camera.

The company NEXYAD Automotive & Transportation has developed an ADAS element for measuring visibility at every moment along the roadside (the assumption being that the roadside is an element that is very important to see) .

Visibility is greatly influenced by contrast, sharp images , and size of objects to be detected . NEXYAD developed a test tool for industrial laboratory : VisiNex .(http://www.visinex.net/)

VisiNex is used to test the effectiveness of a wiper system , demister , defrosting , lighting , ... in the lab to improve the ability of these organs to restore visibility. NEXYAD also developed an on-board module for visibility measurement : VisiNex onboard. The advantage is that this module is that it is calibrated in the lab with VisiNex.

This system " VisiNex Onboard " can be used to :

- Estimate the road risk

- pilot a wiper system , lighting , washing, etc. ...

The value of "VisiNex Onboard" is that the camera is focused on the road scene (and not on the windshield ) , so that the camera can be used for other ADAS functions.

NEXYAD published onboard application on VisiNex technology in 2003 at the ITS Congress Madrid ( " On board visibility assessment for car safety applications: a human vision modeling" , Gerard Yahiaoui Pierre Da Silva Dias, ITS Madrid conference , Nov. 2003 )

For more information : http://www.nexyad.com/Automotive-Transportation

Presentation of VisiNex : http://nexyad.net/Automotive-Transportation/?page_id=159

Contact: sales@nexyad.net

The purpose of demister is to recover the visibility through the windshield. Mist can happen almost instantly on a windshield if the conditions of humidity, pressure , and temperature are met. Mist may go with a transparent veil which lowers the contrast of the image in a translucent veil through which we no longer distinguish objects.

A demister system can implement very different technologies :

- Air conditioning, blowing air on the windshield

- The integrated windshield heating : it is used for a long time on the rear window , and it 's getting on the windshield , with the appearance of transparent conductors embedded in the glass.

The demister testing is traditionally performed "by hand " ( or " by eye" ) : an operator draws contours of the area he considers steamy on a layer placed on the windshield. He is equipped with a stopwatch, and the evolution of his drawing over time reflects the effectiveness of demister . This is a very basic method. In particular, it makes no distinction of transparency : it's either with steam or without steam.

The idea for testing a demister system in a more industrial way is to use a system for measuring visibility. The company NEXYAD has developed such a system (the tester VisiNex ) that was used in the study by the automotive supplier SAINT GOBAIN during the research program SURVIE , labeled by the competitive cluster Mov'eo, and co- funded by the French Government.

The visibility measurement performed by the tool VisiNex is predictive of human feeling and performance. This tool uses mathematical models of the human vision system that needs, in order to detect objects , a compromise between accuracy in luminance (number of gray levels between two levels of light : for a digital camera, it would depend solely on the number of bits) , the available contrast , the size of the objects to be detected.

On the photographs below , we can see the shapes of clouds, although there is no contour and the contrast is low ( but the objects are large and the image is rich of gray levels) . Similarly, the stars are well detected in the black sky , although the objects are very small, there are only two values of gray levels (but the contrast is very high).

very low contrast (no contour and yet we very high contrast (shapes bounded by an edge)

clearly see the shapes of the clouds). Very poor image grayscale, and high contrast.

rich grayscale.

VisiNex estimates a distance of detection, on which can be computed the Johnson criteria to assess the distance of recognition and identification.

NEXYAD also developed a measure called Visual Quality Score ( VQS ) which measures the ease of detecting and recognizing (or read) objects.

Application to test demister :

One generates mist , then one starts the demister . A camera is installed in the vehicle , watching the VisiNex targetsoutside . VisiNex tool measures the change in visibility ( eg VQS ) during demisting :

Comparison of two demister systems : the initial visibility is the

same (same initial mist) and the final visibility is of course

the same ( no more mist )

Similarly, you can compute the visibility score on square areas (eg 5 cm x 5 cm) and make an animated mapping of misting over time.

For more information , contact NEXYAD Automotive & Transportation: http://www.nexyad.com/Automotive-Transportation

Presentation of the VisiNex testing system : http://nexyad.net/Automotive-Transportation/?page_id=159

Contact: sales@nexyad.com

Other applications: test wiper system

(version Française ICI)

A wiper system on a modern vehicle is composed of several modules (motors, windshield with surface is treatment , arms, rubber , rain sensor , brightness sensor , automatic trigger software for automatic wiping mode, ... ) .

If you consider six elements (parts of the wiper system) that can each take 10 references (or adjustments/tuning or location) then you get ten power six possibilities , that is to say 1 million different wiper systems from the same organs.

No doubt that this combinatorial is hard to test in an exhaustive way ...

Moreover, since wiping goal is to restore our vision , it is important to note that the disruption of visibility due to rain are more or less felt depending on the characteristics of the road scene : light level , direction of lighting, size of raindrops , rainfall, vehicle speed, road markings ... Again, life situations are very numerous, so that the crossing (characteristic of wiping ) x ( life situation ) gives rise to a very large number of cases ( more than ten power ten solutions) . The test of this combination is complex as the road is an open area where light rain ... are not controlled , but "suffered".

To proceed to industrial test of a wiper system, it is necessary to control the disturbance of visibility due to rain ( artificial rain machine producing representative and reproducible artificial rain) , and have a test bench on which to implement design plans ( orthogonal and fractional ) to model the impact of setting parameters of the wiper system on visibility.

The French company NEXYAD has developed a tool to measure visibility. This tool ( named VisiNex ) is based on a frequency model of human vision ( within the meaning of the angular frequency ) : The human brain needs a different compromise between contrast and luminance depth ( number of bits in a digital image ) , depending on the size of objects . So are we able to detect a star in the night sky ( very small sized, number of luminance levels equal to two ... that is very low ... , very high contrast ) and gray clouds in a gray sky ( very large number of different gray levels that can shape very weak fine gradients, with low contrast) ..

very low contrast (no contour and yet we very high contrast (shapes bounded by an edge)

clearly see the shapes of the clouds). Very poor image grayscale, and high contrast.

rich grayscale.

The comparison between the available contrast (among angular frequency) in the observed scene and the contrast needed to "see", determines the highest detectable angular frequency , which corresponds to the finest level of detail than humans can perceive . This required contrast strongly depends on the size of the objects to be detected , and on global lighting conditions.

Of course, the perceived available contrast also varies depending on the level of ambient light, and other physical parameters ... and also the person (myopia, etc ...)..

For a given object, the highest detectable angular frequency is the maximum distance of the object that still allows to detect it This defines a visibility distance.

Johnson's criteria are used then to determe if the object can be recognized (eg it's a car ) , and identified ( it's this kind of car )

NEXYAD also defines a measure of the " ease " to detect objects , the Visual Quality Score ( VQS ) , defined as the amount of usable available contrast .

The measurement tools of NEXYAD are based on maths models developed and published by the U.S. DoD since the 60s , validated on panels of observers / human watchmen on detection issues of military objects ( tanks, in particular). By construction, the measure 100% correlates with human impression. NEXYAD recently participated in a research program accredited by the French competitive cluster Mov'eo ( SURVIE project, co -funded by French Government/FUI) , with the partners AXIMUM, CETE, IFSTTAR , OKTAL , SAINT GOBAIN , VALEO , and correlation has been validated for road objects (cars, pedestrians, road markings ).

The theoretical principles used by NEXYAD are published ( 70 theses ... ) and NEXYAD also published applications to wipers testing, and also to onboard wipers control ( ITS publication Madrid , 2003) as an alternative to rain sensors (an because the camera is focused on the road THROUGHT the windshield , not ON the windshield, , it allows you to use the camera for other ADAS functions: the camera and NEXYAD software measures visibility among time, and evaluates how wipers has improved - or not - ).

ref :

- On board visibility evaluation for car safety applications : a human vision modelling approach, Gérard Yahiaoui, Pierre Da Silva Dias, conference ITS Madrid, Nov. 2003

- Mesure de Visibilité, final report of the French research program PREDIT / ARCOS 2004, NEXYAD

- Mesure de Visibilité, final report of the French research program PREDIT / SARI 2008, NEXYAD

- Programme de recherche SURVIE (Mov'eo) sur la mesure de visibilité avec VisiNex, poster at Carrefours du PREDIT, 7 & 8 Oct 2013, Paris

The main difficulties of implementing these visibility measurement models are:

- parameters of the human perception maths models and their variations with the physical and physiological cases are only partially published

- the signal to noise ratio heavily depends on the quality of the calibration (which must allow a sensitive, and repeatable "good measurement")

The VisiNex tool developped by the company NEXYAD was used to test the effectiveness of the wiper system (global, or just one part of the wipers system) by equipment manufacturers (references : Robert Bosch GmbH , VALEO ) and car manufacturers (PSA Peugeot Citroen, Toyota ).

http://www.visinex.net/

On the chart below, you can see the visibility climb at every sweep and then visibility decrease again with the rain :

The curves above show the evolution of the VQS (Visual Quality Score) during a watering cycle (artificial rain) with wiping.

The blue curve is obtained with new brushes , red with exhausted brushes.

One can see that the visibility (measured by the VQS ) is maximum before the rain starts. The slope of decrease depends on the type and strength of the rain (the more it rains the less you see , the more drops are thin the more they disturb visibility through the windshield ) . When the rain stops , curves back up to their maximum value and wipers are switched off. Finally, after a dry duration , the rain starts again without wiping (and VQS decreases again).

You understand that such a measurement tool is used to:

- Testing of concurrent systems

- fixing a wiper system and optimizing efficiency

- validating a wiper system

VisiNex is used in different ways ( with different test procedures ) to test point by point and overall a wiper system. The expected values of visibility may be used to write specifications ( click to enlarge ) :

Chart : Use of VisiNex ( visibility measurement ) in the V-cycle

- Design plans #1: on a reference windshield, constant speed wiping with concurrent brushes and with the new blade. Verification of proper restoration of visibility on a set of reference artificial rainfalls

- Design plans #2 : sending reference rains and recording the output of the rain sensor . Along with this record , measurement of visibility with VisiNex and comparison of the two curves : rain sensor output vs. evolution visibility ( the functional purpose as well as is that the rain sensor indirectly captures the reduction in visibility due to rain ) .

- Design plans #3 : sending reference rains and application of wiping strategies. Validation of the restoration of visibility for each rain through the wiping strategy (again , there is much to be gained by adapting the strategy just enough to get the visibility optimization in terms of engine life and power consumption )

- Design plans #4 : sending scenarios of dynamic changes of light and rain ( simulation of a tunnel entrance , a tunnel exit , start a rainstorm , a "truck " rain cloud type , ... ) , the wiper system set to " automatic mode", and recording changes in the visibility among time.

The time saving and performance improvement lead to more competitive solutions.

For more information, please check the NEXYAD web site :

- VisiNex : http://nexyad.net/Automotive-Transportation/?page_id=159

- Rain Machine RainNex : http://nexyad.net/Automotive-Transportation/?page_id=151

- Nexyad Automotive & Transportation : http://www.nexyad.net/Automotive-Transportation

- Nexyad Testing : http://nexyad.net/NonDestructiveTesting/

Contact : sales@nexyad.net